Fractionated Tire Fuel

Tires are an essential product accompanied by a moderately short lifetime. Without proper management, the disposal of unwanted scrap tires can create significant environmental, health, and safety problems. The process of burning scrap tires enables the ability to provide energy but consequently produce potentially hazardous emissions.

MSCPA has teamed up with Symbiotic Energy LLC to help put an environmentally friendly end to scrap tires. Symbiotic, an Ohio based organization has developed a unique patented process that converts tires directly into a clean gas fuel and recovers the high-quality steel belts for reuse, all while generating minimal emissions.

The process is called “tire fractionation”. This closed loop system controls the exposure of tires to heat, thus converting the non-metallic portion of the tires to gaseous fuel and carbon particles without using combustion.

MSCPA has teamed up with Symbiotic Energy LLC to help put an environmentally friendly end to scrap tires. Symbiotic, an Ohio based organization has developed a unique patented process that converts tires directly into a clean gas fuel and recovers the high-quality steel belts for reuse, all while generating minimal emissions.

The process is called “tire fractionation”. This closed loop system controls the exposure of tires to heat, thus converting the non-metallic portion of the tires to gaseous fuel and carbon particles without using combustion.

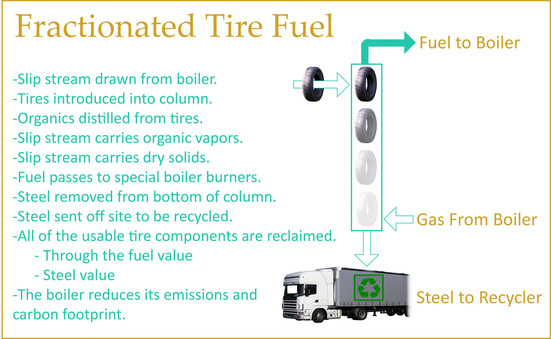

Symbiotic explains how the procedure works:

"Whole tires are suspended on a vertical conveyer system and lowered through the column. By the time a tire reaches the base of the column, the heat has converted the entire organic portion of the tire to a gas and fine carbon particles. The gas has a sufficient energy value to serve as a fuel, and is piped to the boiler for combustion. The metallic belts in the tire are not combusted or converted to gas, but rather accumulate at the bottom of the column and are later removed for recycling offsite. “

Due to the absence of combustion, this process is one of the newest contributions to energy diversity and reduced emission of greenhouse gasses. Generating fractionated tire fuel will convert 4 million scrap tires (annually) into an environmentally friendly and relatively inexpensive form of fuel. That is roughly equivalent to using 1/3 of Michigan’s scrap tires per year. Also, 6,000 tons of class one scrap steel will be sold as a byproduct to local steel mills and foundries every year.

For more information, check out Symbiotic Energy’s website, click here.

"Whole tires are suspended on a vertical conveyer system and lowered through the column. By the time a tire reaches the base of the column, the heat has converted the entire organic portion of the tire to a gas and fine carbon particles. The gas has a sufficient energy value to serve as a fuel, and is piped to the boiler for combustion. The metallic belts in the tire are not combusted or converted to gas, but rather accumulate at the bottom of the column and are later removed for recycling offsite. “

Due to the absence of combustion, this process is one of the newest contributions to energy diversity and reduced emission of greenhouse gasses. Generating fractionated tire fuel will convert 4 million scrap tires (annually) into an environmentally friendly and relatively inexpensive form of fuel. That is roughly equivalent to using 1/3 of Michigan’s scrap tires per year. Also, 6,000 tons of class one scrap steel will be sold as a byproduct to local steel mills and foundries every year.

For more information, check out Symbiotic Energy’s website, click here.